MECANO ID

MECANO ID

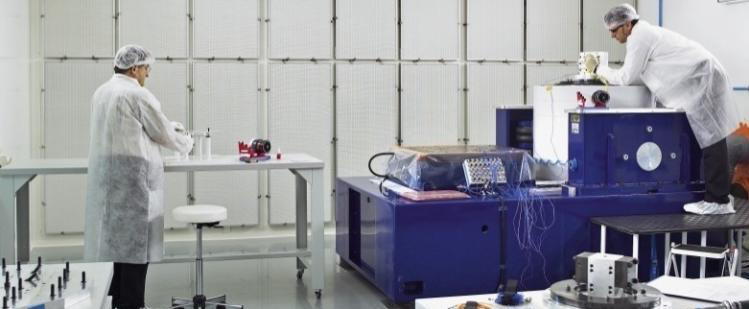

MECANO ID provides several testing means to perform mechanical and thermal environmental tests for its customers: three shakers, a metal/metal impact SRC-shock bench, a half-sine shock bench, a space simulator for thermal balances and cycling, a dedicated chamber for equipment bake-out, a climatic chamber.

The three shakers have a maximal capacity range from 14 to 72kN. Two are implanted in controlled environments: one in ISO8 (hood) and the other in ISO5 (laminar flow). With up to 64 measurement channels, our monitoring and acquisition system meet the needs for highly instrumented tests involving manual or dynamic notching.

Our metal/metal impact bench (in-house design) enable to perform SRC shocks from hundred to thousands gSRC and for frequencies between 800 and 4000Hz. Implanted in ISO8 environment, it enables to meet the requirements from space industry.

Our half-sine shock bench enable to validate the components transfert with levels from 500 to 3000g.

The 3 thermal chambers are implanted in ISO8 controlled environment.

The thermal vacuum one (2m3, 1200x900mm, -165°C;+165°C, P< 1×10-5mbar, cooling trap) enables to perform thermal cycling with instrumentation up to 60 TC.

The bake-out one (900x600mm,Tmax +165°C; P< 1×10-5mbar) is dedicated to equipment bake-out through quartz crystal microbalances TQCM (bake out) to meet ESA standards F’’/F<1%.

The climatic one (900x950x900mm, ambient pressure under N2, -55°C;+180°C, 18 TC max) is adapted to standard equipement cycling.