MECANO ID

MECANO ID

< Back to the products catalog

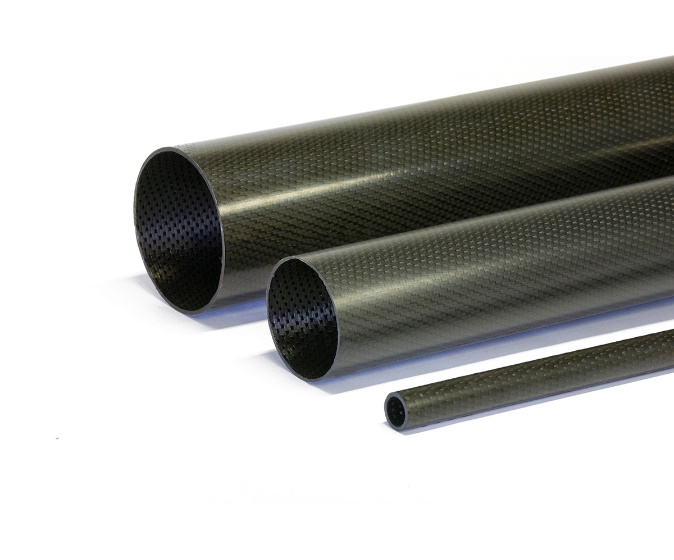

With more than 10 years of flight heritage, our space qualified carbon tubes ensure high quality, high performance and low weight of the structures they compose. Serial manufacturing is now possible thanks to the development of AFP (Automated Fiber Placement) means.

Space Carbon Tubes are manufactured by MECANO ID from Carbon fabric, Carbon fiber and Epoxy resin using RTM (Resin Transfer Molding) process. These tubes are space qualified.

Our own specific manufacturing processes and tools ensure uniform and repeatable high quality level. With the investment of new means enabling AFP (Automated Fiber Placement), both manual and robotized layups are available.

Our space qualified tubes are validated by a series of acceptance tests: mechanical compression, ultrasonic, micrography, void volume ratio determination and differential scanning calorimetry (DSC).

In accordance with performance requirements of the application, carbon tubes allow weight savings, temperature and corrosion resistance.

Three levels of development are provided: